Eco Epoxy Resin 1 L

Bamboo Bicycle Club Team

1kg Kit

LB2 Epoxy Laminating Bio Resin is medium viscosity and optimized for hand laminated applications, while it is compatible with all common fibre reinforcements it is particularly well paired with flax reinforcements to provide composite parts with a significantly reduced environmental impact.

Our bio resins are not compromised in performance but simply derive the same chemicals from plant-based sources. A key component of epoxy, epichlorohydrin, is manufactured using renewable plant-based Glycerol in place of petroleum-based propylene. Additionally, the raw materials going into our bio resins are co-products or waste products of other industrially important processes which means they do not compete with food sources or displace food-based agriculture. The resin component contains 35% plant based content. Once mixed with its hardener the overall plant-based content is ~27% which is amongst the highest in the industry.

LB2 is a high-performance bio epoxy resin suitable for use with a wide range of reinforcements including glass, carbon and aramid fibres as well as natural reinforcements such as flax and jute fibre. Its viscosity profile is particularly suitable for hand laminating and bonding applications including open hand layup and vacuum bagging processes. For resin infusion or RTM processes we have another Bio Resin, IB2, which has a lower viscosity and a cure profile that is better suited.

Uncompromised mechanical properties compared with conventional ‘non-bio’ epoxy resins. Compatible with carbon, glass, aramid and natural fibres, Hand laminating, vacuum bagging and bonding. Sustainable Resins for Greener Products

SPECIFICATION

Product Data

| Colour | Clear | |

|---|---|---|

| Chemistry / Material | Epoxy | |

| Viscosity | 190 | mPa.s |

| Brand | Easy Composites | |

| Bio-Based Carbon Content | 35 | % |

| Shelf Life | 24 | Months |

Cured Mechanical Properties

| Max Service Temp | 90 | °C |

|---|---|---|

| Impact Resistance | 25 | kJ/m2 |

| Flexibility | Hard / Rigid | |

| Tensile Strength | 78 | MPa |

| Tensile Modulus | 3.23 | GPa |

| Elongation at Break | 5.8 | % |

| Flexural Modulus | 3.2 | GPa |

| Flexural Strength | 127 | MPa |

| Interlaminar Shear Strength | 52 | MPa |

| Compressive Strength | 107 | MPa |

| Tg Onset (DMA) | 90 | °C |

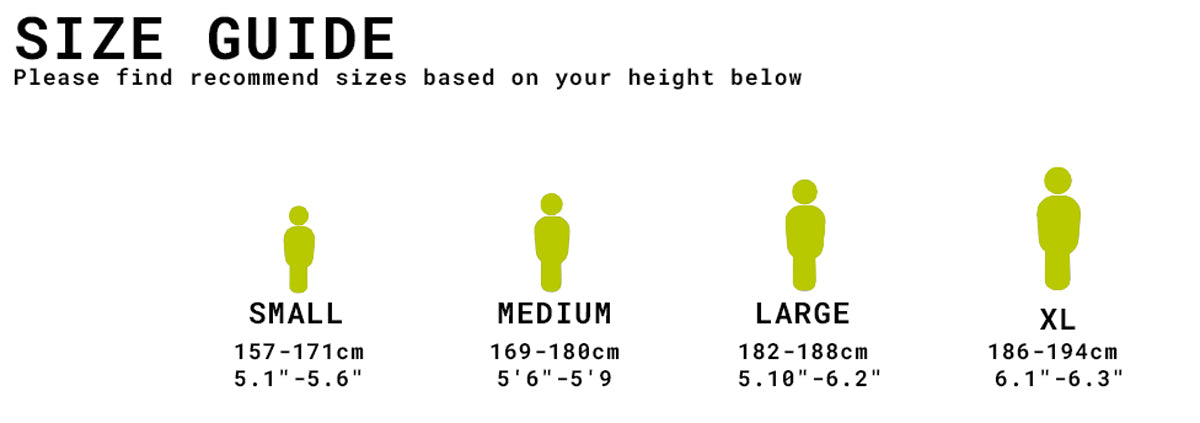

Frame Sizing Guide

If you are in between two sizes we recommend going for the smaller size as you can adjust the frame fit on smaller frame but if the frame is two large then you may be unable to adjust. Alternatively choose a custom frame.

Bike Geometry - Introduction

Frame sizes are referred to as geometry, the geometry encompass the shape, length and the angles of the frame. Each frame type will have certain angles and measurements to give you a ride characteristics associated with the frame type.

A road bike will typically move the rider into a more forward position (seat and head tube angles of 72/73 degrees) to maximise power transfer and elongate the rider to improve aerodynamics.

A dutch style bicycle will be another extreme of geometry moving the rider further back (seat and head tube angles of 68 degrees) on the frame to suit relaxed riding and flat terrain as well positioning the rider in a upright position.

You can read many books on geometry! This a brief insight. Try and select a bicycle that suits your requirement and the geometry should match. E.g Road bike for road usage, gravel for mixed on and off road, MTB for off-road trails.

How to check your fit for a frame.

The key measurements used for a stock frame are you inside leg and overall height.

Height

- Simply stand upright in bare feet, with your back against a wall/doorframe.

- Place a pen or pencil atop your head and parallel to the floor.

- Make a small mark on the surface and measure.

Inside Leg

- In bare feet; stand upright with your back against a wall.

- Place a book/ruler between your legs and level with your crotch.

- Have someone measure the distance from the top of the book/ruler to the floor.

If you find that you fall between 2 sizes, the general rule of thumb is to opt for the smaller size. Why you may ask? Well, it’s because it’s generally considered easier to make a bike that’s a little small fit than one that’s too large. There are certain alterations that you can make to a smaller bike to correct the sizing.

These include: lengthening the stem length, crank length and raising the saddle height. It is much more difficult to adjust a bike that is too large to fit the rider. After all, a seat post can only drop down so far. Whereas fitting too short a stem can result in overly responsive (twitchy) steering.

More about components - Traditionally frames would be built at a local bike shop and the frame would determine the fit with fixed component options.

With modern compact frames most of the final frame fit will be done with components to adjust the position of the rider using a broad range of component options like, seatpost type, stem length, handlebar width etc.

Drop us a email to info(@)bamboobicycleclub.org with any questions